The floors in manufacturing and logistics operation buildings are sometimes like arteries in the human body – without them, the blood circulation would collapse. Of course, they do not distribute oxygen, but thanks to their quality, it is possible TO CONTINUOUSLY WORK WITH FORKLIFTS, an important part of the logistics of materials, goods, and services. Statistics of work accidents confirm that overturning of forklifts and other accidents of these mechanisms are often fatal. How to prevent them from the very beginning – when planning and building a future operation building?

Warehouse accidents are a real nightmare. If you don’t believe it, just look for official statistics on accidents and injuries in the workplace or browse videos on popular Internet channels. Some give you the shivers … They need to be prevented from the ground up.

Safety above everything else

Many aspects are affecting the safety of forklift operations. Speed control, permitted and forbidden zones, clearly marked lanes, safety regulations for handling loads, and other rules for accident prevention. However, the parameters and characteristics of the contact area during the movement of the manipulator, which is the concrete floor, in a specific operation building, are far from the least important.

Proper geometry and floor finish are the main factors that affect the safety of wheel handling equipment. Ensuring both factors is a question of the contractor’s experience and accuracy in the implementation of work. The exact opposite is also relentless: a floor made unprofessionally, without the necessary knowledge, can have pitfalls and hidden threats, which will ruthlessly wait for the industrial moving trucks.

It doesn’t have to be a loss of human life or a serious accident at work. The result can be material damage, financial losses, time delays, but also a complete paralysis of the operation with subsequent dismissal of employees…

Expansion and connection solutions

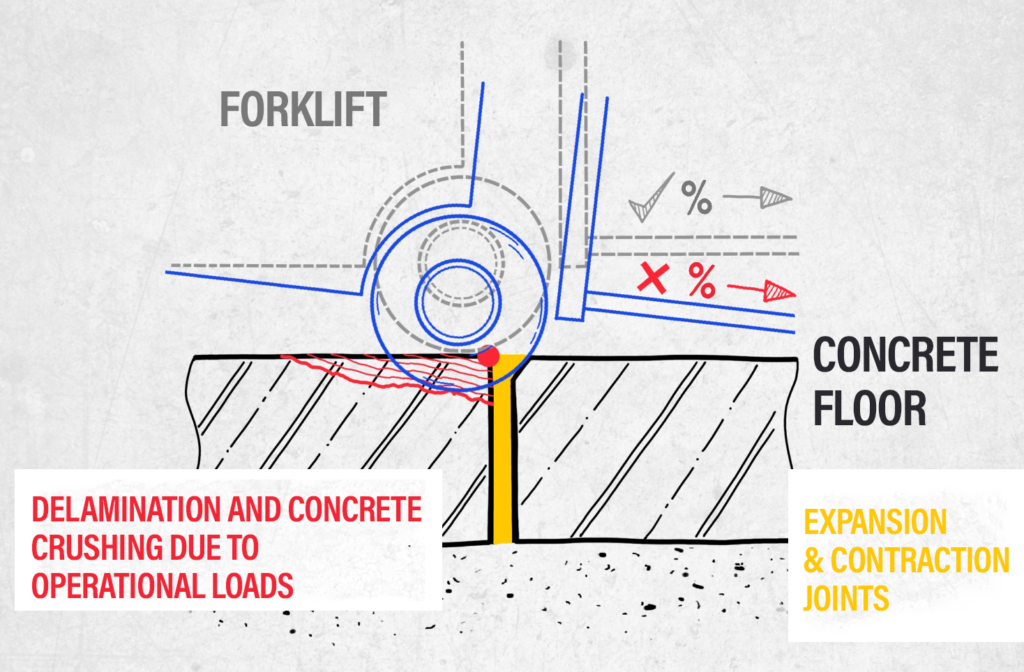

There are always places on the floors that are significantly more prone to wear off and tear, which is directly related to the nature of the operation. These are usually the borders of the contracting, or expansion units, but also, for example, drainage connections, etc.

The higher the exposure of the load, the faster the onset of signs of wear. Unfortunately, the main problem in the floor construction phase remains the unprofessional design of construction details. The concrete is then unnaturally loaded during operation.

Compliance with slopes

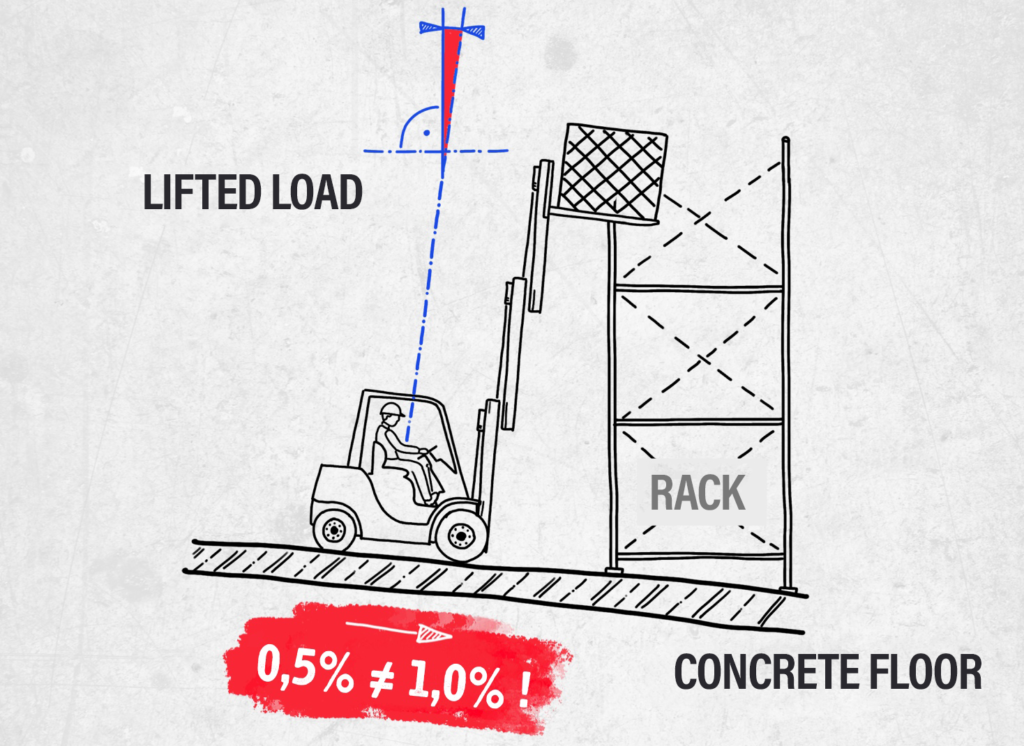

The most common activity of forklifts is moving and handling loads that are lifted into racks at a height of 6 meters or more. The center of gravity of the truck with such a high load is prone to deflections from the calculated slopes, despite modern gyroscopic compensators. If the floor surface has poor flatness, problems arise when driving and then when loading loads into the racks.

Did you know?

Designers dimension the floor slopes about drainage, and it is important to adhere to them during implementation. Otherwise, the water will not be able to drain away, and the handling of the forklifts will deteriorate again. The highest accuracy of slopes and flatness in the implementation of floors can be achieved using modern technologies – LASER SCREED machines. These are laser-guided devices for vibrating concrete mixes.

Proper surface treatment

When designing a floor for operation with forklift trucks, the following should be considered:

1. Floor resistance

The force of static and dynamic loading by a loaded truck requires the use of a higher strength class of concrete. The reinforcement elements in it must also correspond to the load. In case of insufficient resistance of the floor, there is a risk of excessive deformation and loss of flatness, which ensures the smooth running of the trucks.

2. Surface treatment

The degree of adhesion of two materials is technically called the coefficient of adhesion. Its value is important when assessing the material of the truck wheels and the floor finish. The choice of the type of concrete floor treatment must be made with regard to the given coefficient. There should be no unwanted movements when driving the truck. For example, getting into a skid in curves or too long braking distances. Suitable types of adjustments include:

- polymer-cement coating,

- cement coating,

- polyurethane coating,

- armored concrete floors.

How to not mess it up

“Just a little something” can have a significant effect on the smooth running of forklifts and their ability to move safely with loads. Small but essential construction details of the floor can make the ride more graceful but also create an obstacle. Keep in mind that the expertise of the concrete floor contractor is as important as the competence of the forklift operator itself.

Safety and health at work are never outdated topics. Although it cannot be secured one hundred percent, it can be brought as close to it as possible. Concrete floors and their surface finishes are among the factors that can have a direct impact on safety at work and human life wherever forklift trucks are used – in any industry, manufacturing, logistics, or services. Let us not underestimate their role. Always pay attention to choosing the right one.

We write about industrial floors professionally and clearly.